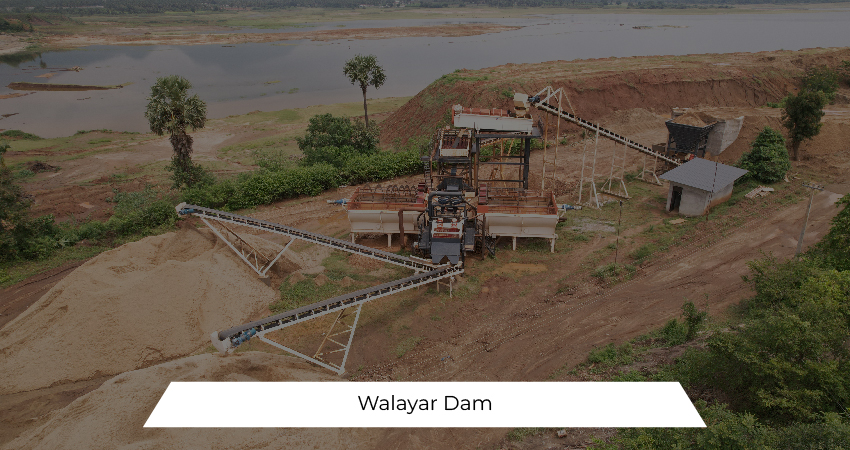

Project Overview and Partnership

The Kerala government has embarked on an ambitious project to enhance the capacity and functionality of the Walayar Dam. The project has been allocated to Sri Avantika Contractors, who are responsible for deepening the dam, increasing its storage capacity, reducing sedimentation, and recovering valuable resources. A key aspect of the project involves the efficient recycling of dredged sand. For this purpose, Hailstone Innovations has been selected as the strategic partner, leveraging their expertise in sand processing technology. The collaboration aims to produce high-quality M sand and P sand, essential components in modern construction, with an output capacity of 200 TPH.

Advanced Machinery and Equipment

The plant incorporates a range of advanced machinery to ensure efficient sand processing and separation. The Hailstone Blade Mill (HBM 3020T) plays a crucial role in handling sticky feed material, transforming it into a water-mixed slurry. This slurry is then directed to a single incline screen for meticulous screening. The screened material is fed into the Bucket Classifier (BC 1815), which further refines the product. The Hydrocyclone Washing System (HWC200) is another critical component, equipped with a Rinser Screen (RS480211) that separates the sand into two distinct grades: 2.5 to 4.5 mm and 0 to 2.5 mm. This system ensures the production of well-defined, high-quality sand tailored to specific size requirements.

Efficient Process and Product Quality

The design of the sand separation process is highly efficient, ensuring that each piece of equipment works seamlessly with the others. The feed material first undergoes a transformation in the Blade Mill, which helps manage sticky materials by turning them into a slurry. This is crucial for the subsequent separation stages. The meticulously screened output from the incline screen is then processed in the Bucket Classifier, which removes excess moisture and impurities. The Hydrocyclone Washing System further enhances the quality of the final product by ensuring thorough washing and precise separation into the required sand grades. This comprehensive process results in high-quality M sand and P sand, ideal for various construction applications.

Collaboration and Project Success

The success of the Walayar Dam project heavily relied on the close collaboration between Hailstone Innovations and Sri Avantika Contractors. The design and implementation of the separation plant were tailored to meet the specific needs of the project, with each component carefully selected and integrated to optimize performance. Hailstone's team worked closely with the customer throughout every step of the process, ensuring that the plant not only met but exceeded expectations. The use of modular products, including bespoke dewatering screens, allowed for the production of premium-quality sand. This collaborative approach and attention to detail were vital in achieving the project's goals, delivering a reliable and efficient solution for sand recycling and processing.