Published Date: Oct 28, 2024

Published by: HSadmin

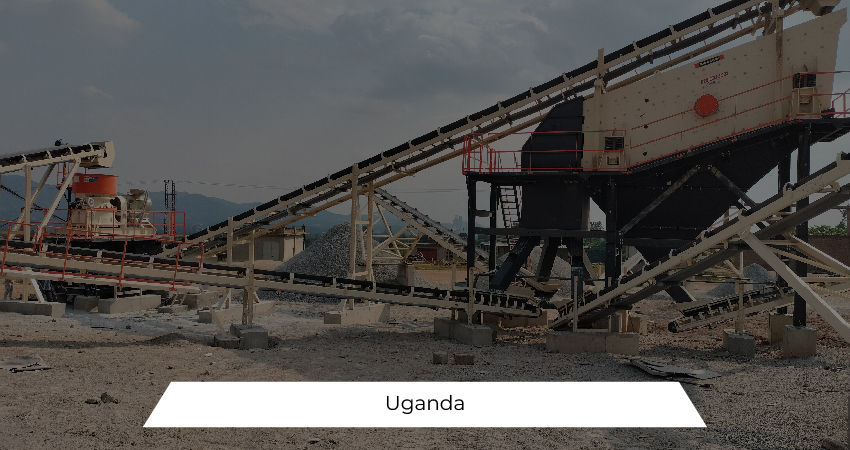

Ram Construction, a valued customer based in Uganda, relies on Hailstone's 2-stage crushing and screening modular plant to achieve the desired end-product within a confined space. This modular plant, designed to be compact yet efficient, has been successfully installed despite the spatial constraints of the site. The modular design has enabled Ram Construction to produce four distinct aggregate products, meeting their diverse project needs. With the ability to operate in a limited area without compromising on output quality, this installation has proven to be a game-changer for the company's operations.

The site consistently produces between 80,000 to 100,000 metric tons of product each month, a testament to the efficiency and reliability of Hailstone's equipment. Central to this operation is a 250 TPH compact modular plant, which includes key components such as the JC 140 Jaw Crusher, HF 270 Cone Crusher, GFEM 4812 Grizzly Feeder, and VS 600 200-4D Screen. Additionally, the high-capacity 3000-ton stockpile with PFVM-2210-2 NOS ensures that the site can handle large volumes of material effectively. This setup not only maximizes productivity but also ensures a steady supply of aggregate products for Ram Construction's various projects.

The versatility of Hailstone's plants has proven invaluable for Ram Construction, allowing them to adapt to varied rock abrasiveness with ease. This adaptability is further enhanced by the robust support provided by the Hailstone team, ensuring that any operational challenges are swiftly addressed. Whether producing granular subbase or specific aggregate sizes, Ram Construction has consistently met their construction requirements efficiently. The combination of Hailstone's innovative technology and dedicated support has empowered Ram Construction to maintain high productivity levels and meet their project deadlines successfully.